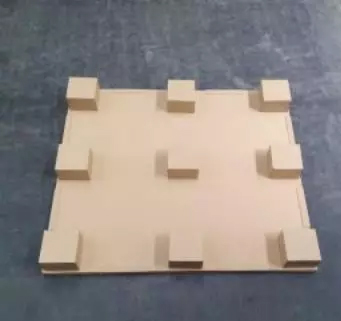

In the past few decades, the transition from wooden pallets to plastic pallets has begun. There are many reasons for this transition, including cost, function, and environmental reasons. Although the initial cost of plastic pallets may be higher than that of wooden pallets, the service life of recyclable plastic pallets is longer. In industry, the plastic pallet mould's moulding process include rotational moulding, injection moulding, structural foam, compression moulding and profile extrusion.

The injection moulding machine includes a heating barrel with a rotating screw. The raw materials and colorants melt together in the barrel. The molten plastic is then injected into the clamped pallet mould and pressure is applied. Copolymer polypropylene or high-density polyethylene resins are commonly used for injection-moulded pallets. The cost of high-pressure injection pallet mould is high, but the cycle time of the process is short.

Structural foam moulding is a form of low-pressure injection moulding. The cavity is filled with polyethylene or polypropylene plastic particles and nitrogen. Heating activates the blowing agent, thereby producing a core with a firm skin. This method requires fewer raw materials and can also produce plastics with a higher strength/weight ratio. The low pressure injection pallet mould itself is cheaper than the mould used for high pressure injection moulding.

The most common thermoformed pallets that anyone can see are U.S. Postal Service pallets, but many supermarkets also use them. Thermoforming pallet mould is much cheaper than injection mould, but the cycle time is slower. Thermoformed plastic pallets are usually very lightweight and durable. The two-plate thermoformed pallet is hollow, and if it is pierced and exposed to rain, water may accumulate.

The most common thermoformed pallets that anyone can see are U.S. Postal Service pallets, but many supermarkets also use them. Thermoforming pallet mould is much cheaper than injection mould, but the cycle time is slower. Thermoformed plastic pallets are usually very lightweight and durable. The two-plate thermoformed pallet is hollow, and if it is pierced and exposed to rain, water may accumulate.

Compression moulding is used to make plastic pallets and shaped pallets made of other materials such as wood chips and resin. In the compression moulding process, many different types of recycled materials are used, including various plastics, rubber, synthetic resins and other recycled waste products.

Compression moulding is used to make plastic pallets and shaped pallets made of other materials such as wood chips and resin. In the compression moulding process, many different types of recycled materials are used, including various plastics, rubber, synthetic resins and other recycled waste products.

The rotational moulding process can be traced back to the early 1970s. First, the granular or powdered plastic material is filled into the mould. The mould is heated and rotated in two planes perpendicular to each other. This helps distribute and fuse the material into the mould. Pallet moulds for rotational moulding are generally cheaper than other processes.

Profile squeeze pallets look very similar to wooden pallets and are constructed in a similar way. The raw material is melted and then forced through the extruder. After cooling, the extruded material is cut into wooden size and fixed with nails, screws, glue or heat welding. Recycling recycled materials can reduce costs, and adding wood fibers or other materials to extruded profiles can increase stiffness.

Profile squeeze pallets look very similar to wooden pallets and are constructed in a similar way. The raw material is melted and then forced through the extruder. After cooling, the extruded material is cut into wooden size and fixed with nails, screws, glue or heat welding. Recycling recycled materials can reduce costs, and adding wood fibers or other materials to extruded profiles can increase stiffness.